- Home

- Solar Energy

- Hybrid Solar Lighting

Hybrid Solar Lighting

Natural Replacement Illumination

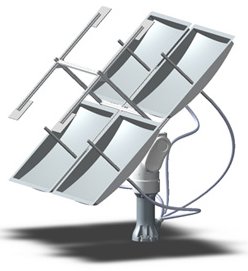

Hybrid solar lighting in a special arrangement focuses sunlight to replace and augment interior lighting. The goal is to greatly decrease the electrical cost of lighting - a significant proportion of total power use in commercial and retail operations.

Developed by Oak Ridge National Laboratory, who also hold the patents, the main commercial distributor is now Sunlight Direct in California. Mirror technology was provided by New Zealand company Bennett Mirror Technologies now trading as Duravision™ Mirror Systems.

Photo courtesy of Duravision Mirror Systems

From mid 2011 Melbourne, Australia has been introducing the technology in lighting public buildings.

Sunlight Redirected - History

Over the years many methods have been employed to utilize natural sunlight for lighting the interiors of buildings.

Various window technologies like clerestory windows, skylights and their more recent variation - the light tube - and smart glass which darkens with direct light to reduce strong direct sunlight are still employed.

Other methods redirect external sunlight whether by flat mirrors, or more complex curved mirrors that move to track the sun (heliostats) into each window. Even fiber optics placed within concrete walls have been used.

Oak Ridge's Hybrid Solar Lighting

Oak Ridge National Laboratory (ORNL) began the initial development of hybrid solar lighting.

The basic design was a parabolic mirror geared to track the sun to maintain maximum input. At the focal point a central mirror then reflected light to the collecting area which then fed the light down an array of fiber optic cables which lead into the building.

A similar idea was tried in Japan in the 1970s. Limitations in technology prevented delivery of an effective commercial system.

ORNL's breakthroughs were in using cheaper and lighter materials.

A heavy glass parabolic convex mirror could be replaced with a much lighter and cheaper acrylic one - provided by the three generation family business of Bennett Mirror Technologies in New Zealand.

Glass fiber optic cables could be replaced with plastic ones.

More complex tracking gear was simplified. The tracking motor could be powered by a 12 or 24 volt power source requiring only 2 Watts. Even this could be supplied by a small photovoltaic panel. The goal was to reduce the weight and cost of the unit as much as possible.

Commercial Applications

The best application for hybrid solar lighting is in commercial and public buildings which are used extensively during the day. Being larger constructions exterior light does not penetrate far into the building. Regular windows and skylights have relatively little total benefit.

Power use for lighting in commercial buildings can be 20% of total power requirements.

In retail, especially where a lot of display lighting is used, electric lighting can consume 55% to 70% of the business's total power requirements. A great deal of this demand arises from the more tungsten-based spot display lighting which has been shown to increase sales.

Massively reducing these lighting costs will save also on power generation with its associated environmental effect from the carbon footprint of the generating source. More recent developments in LED lighting can make these savings and combinations even more effective.

Delivery Limitations

Delivery of hybrid solar light is limited to around 50 feet (17m) of fiber optic cable. Losses for longer distances make it less effective. This limits the technology to a couple of storeys, or floors, of a multi-storey building.

Illumination is augmented by the usual surrounding light as it is needed. Ideally best conditions should not require the use of supplementation. Cloud cover might demand use of only 5% of accessory lighting.

Savings will be greatest with installations that have been or require using tungsten fittings. There are still significant cost savings with the less ideal fluorescent versions.

The hybrid solar lighting fixtures have been designed with 127 fibers per unit. Each unit should effectively light 1000 square feet (100m2).

Being fiber optic cables these can be directed to many different areas depending on requirements. Increased illumination, like spot effects, can be achieved by using more fibers at each point.

Hybrid solar lighting fixtures are designed to eliminate at the intake the ultra-violet and infra-red portions of the sunlight spectrum. These portions can be used for the buildings' space heating and water heating requirements. It also means the illuminating light is cool, and does not add unnecessary extra heat load to the building.

Image courtesy of Sunlight Direct LLC

Sunlight Direct from California shows some variation on the original circular parabolic reflective mirrors for their hybrid solar lighting. They have images of more rectangular mirrors. But even these still have the same basic collectors and tracking.

LED's Advantages

As LED light technology has been moving rapidly in recent years, there is more scope for matching the sourced sunlight.

Although many commercial buildings use fluorescent lights, better colour matching and spectra will be achieved with LEDs. The same is true for retail spot lighting.

Power consumption with LEDs, especially with new emitters coming on-line now, is massively reduced.

Costs

When ORNL installed its pilot hybrid solar lighting units in parts of the USA around 2006 each unit cost $24,000. The projection was these units should cost only $3,000 by 2012.

Regions that would benefit the most from the units would be those with plentiful sunlight and states and areas with relatively high costs for electrical power distribution.

- Home

- Solar Energy

- Hybrid Solar Lighting